Merging Design Technologies to Fast-Track Transit Project in Fast-Growing Seattle Area

Unique, nontraditional, and highly coordinated BIM process helps Sound Transit’s new Operations and Maintenance Facility take shape

Transit options in large metropolitan areas are in a race to expand to accommodate their growing populations. In the Greater Seattle area, for example, our team is working on a project for Sound Transit that will give momentum to a 25-year, region-wide system expansion program that includes 116 miles of light rail, a new Bus Rapid Transit program, and extended commuter rail service.

Seattle is a gridlocked, growing metropolis—and it’s getting more congested every day. In fact, Seattle has been named the fastest-growing city in the United States this decade, adding more than 114,000 residents since 2010. The Sound Transit Operations and Maintenance Facility (OMF) East will transform transportation services for the Puget Sound area. The light rail vehicle (LRV) fleet will expand from 62 to 184 vehicles, help connect communities, and make work opportunities in and around Seattle more accessible to the local and surrounding communities. So, what’s the secret sauce when taking on a transformative $220 million design-build project? The innovative use of leading-edge digital technology.

When working on a project of this scale, coordinating a wide variety of services and designs onto the build site is no easy task. To help overcome this obstacle, our team used an inventive combination of modeling and design review tools—such as Revit, Civil 3D, Navisworks, iConstruct, and Revizto—in a BIM process in unique and nontraditional ways.

Innovative use of BIM: Modeling above and below ground

Innovative use of BIM: Modeling above and below ground

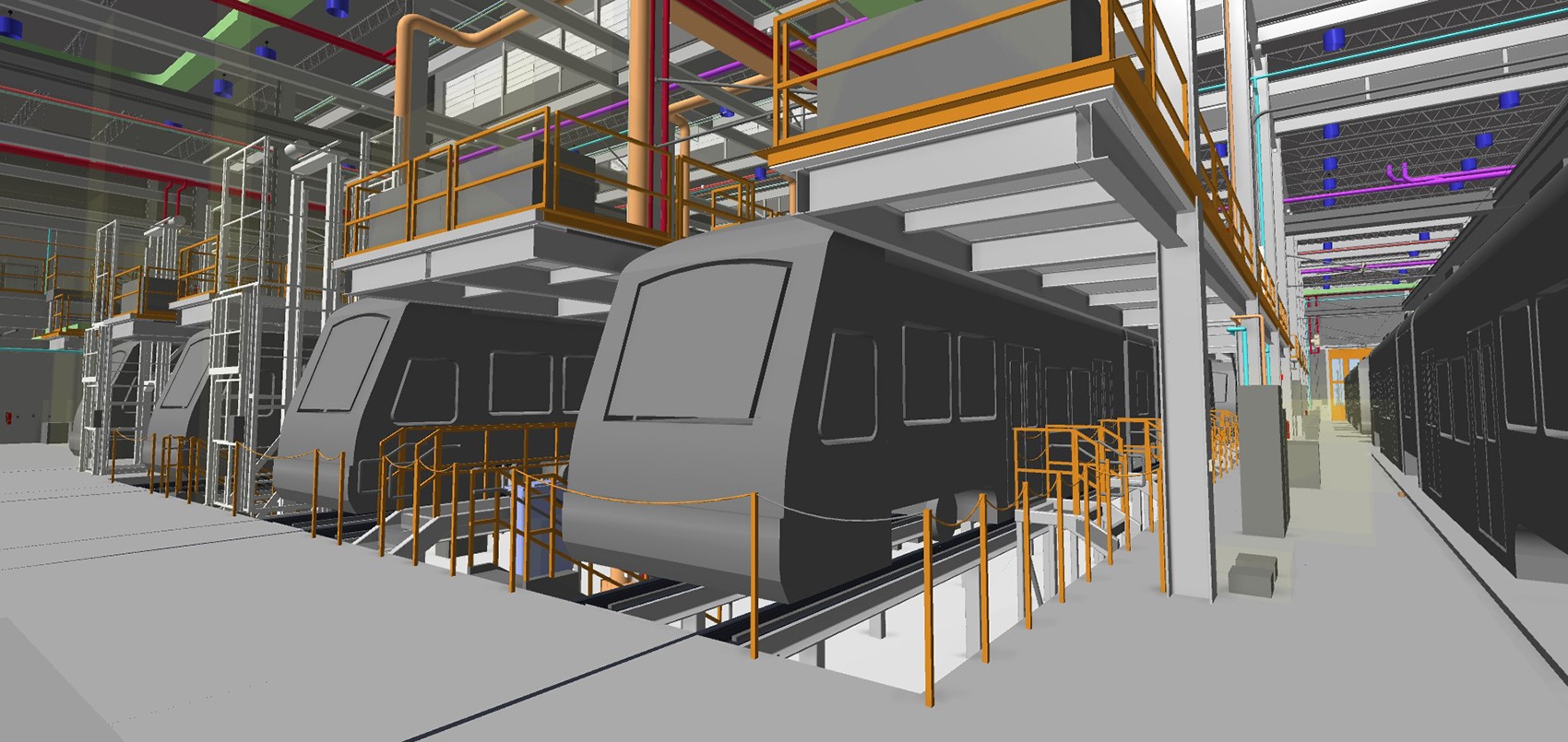

The site for the project was relatively constrained but still needed to accommodate a considerable number of coordinated structures, utilities, and services. The team agreed that a high degree of modeling and collaboration was necessary to achieve a coordinated design solution.

The use of modeling tools in design is hardly new. What we found exceptional and exciting about this project, however, was the way in which our team brought each of the diverse modeling platforms together. This made the collective design and coordination process better and more efficient.

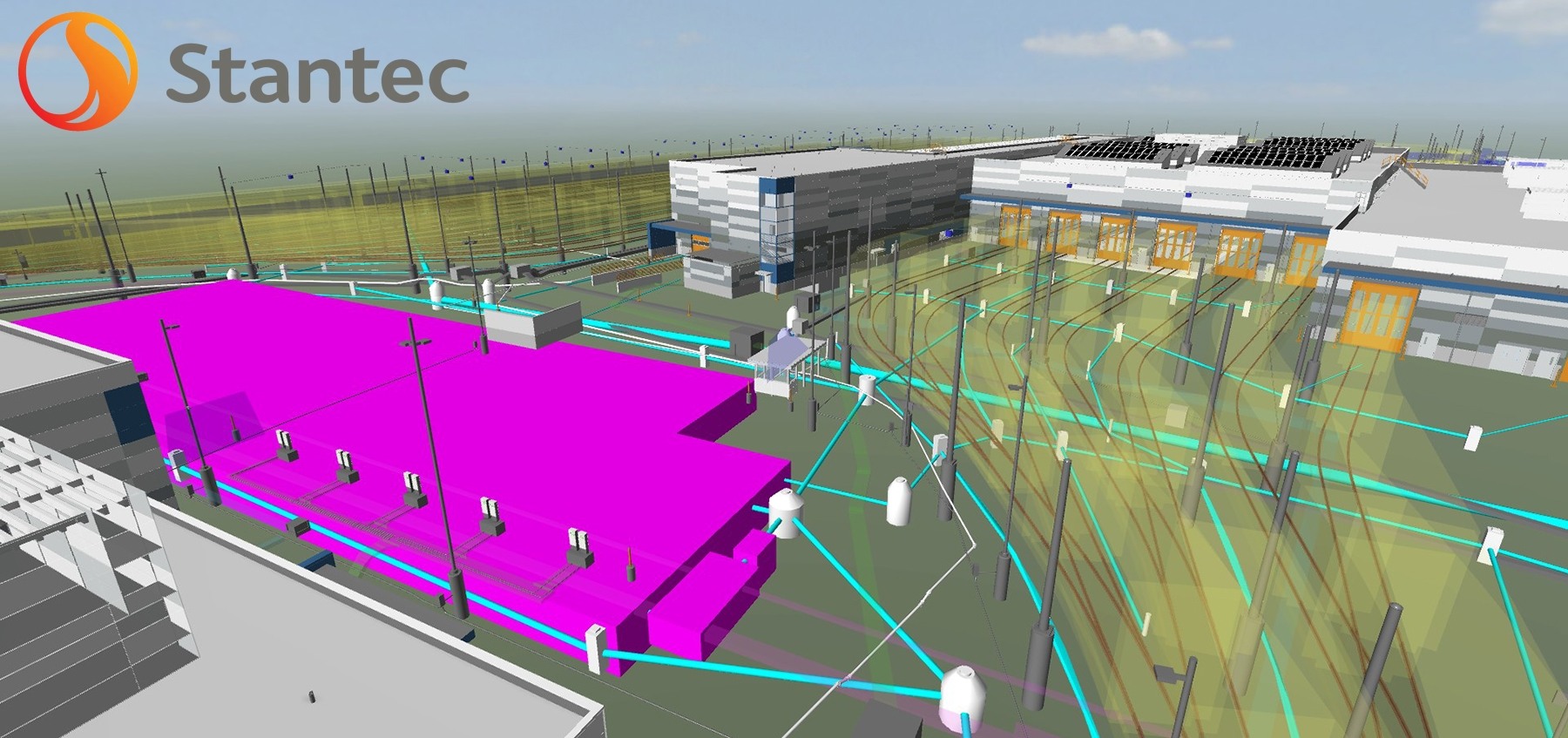

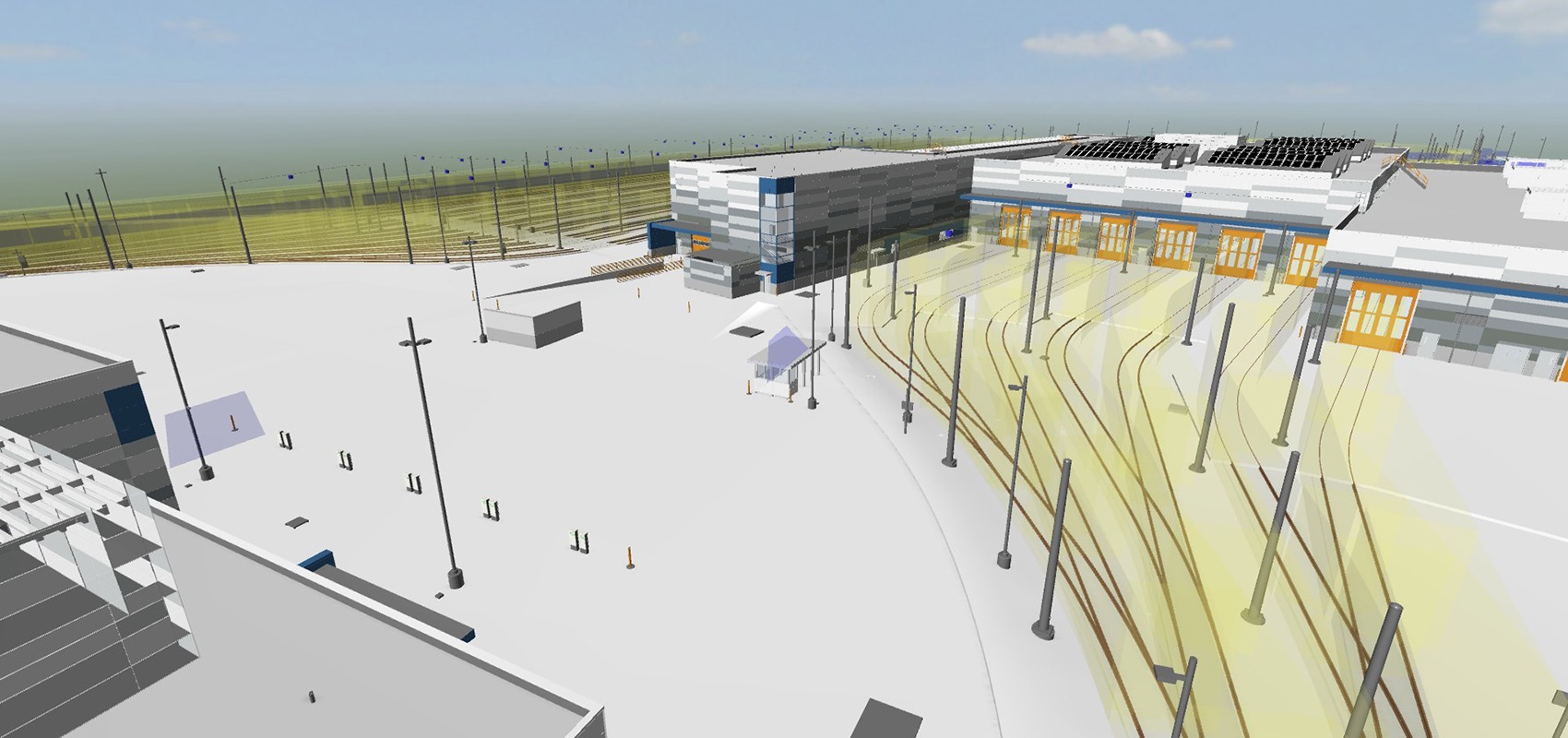

Revit was used to model each of the buildings and their internal systems—architecture, interiors, industrial equipment, structural, mechanical/electrical/plumbing, electrical services, and information and communications technologies. Civil 3D was used to model site surfaces (underground storm, sanitary, water, and gas lines), as well as underground tanks and structures. Track alignments and LRV dynamic envelopes were also modeled. Each of these models was authored by a team distributed across three time zones in seven cities and two countries, and in no fewer than 60 model files.

The challenge? Bringing these diverse components and platforms together in a way that enabled stakeholders to interact with the entirety of “the model”—regardless of locale, proficiency, or availability of any modeling software—and without the burden of file-exchange or version control. Enter Revizto.

“The ability to visualize and identify issues early and across the entire facility saves thousands of dollars in change orders and construction delays.”

Collaborating in Revizto

The team decided to implement Revizto early in the design phase. It’s an easy-to-use, secure, file-neutral, cloud-based, model-review solution. Model files were published to Revizto, unattended, every night. Each day, the design-build team and Sound Transit could visualize the current design in all areas of the facility. We saw a vast improvement in collaboration and engagement because the model was accessible to anyone, from anywhere, at any time.

Revizto also incorporates an “issue-tracker.” Whether it be a minor design conflict, trivial modeling error, or critical issue, stakeholders could raise a concern and assign it to any other stakeholder for resolution. Extending this functionality, the team could push clash results found in Navisworks and iConstruct to Revizto’s issue tracker for subsequent assignment, prioritization, and follow-up. In effect, Revizto’s issue tracker became a one-stop-shop for model-issue and clash management. Typically, a team might use Revizto to coordinate a single building model. But our team took that a step further by using it for the entire site—multiple buildings, the site, the tracks, and the underground utilities.

This is a process we intend to implement across our suite of transit projects going forward, changing the way we do work by building it into our mindset from the start. By using Revizto at the very early stages of design, we were able to facilitate a level of teamwork and collaboration that was instrumental in helping us to meet deadlines, stay on track, and stay in lock-step as a project team.

Leveraging technology to save time and money

By utilizing Revizto in conjunction with standard modeling tools, the team could see the entire facility come together during the design process. It goes without saying that the ability to visualize and identify issues early and across the entire facility saves thousands of dollars in change orders and construction delays.

When we use technology in creative ways, the positive results are as clear to the client as they are to the team. From day one, the team was better prepared to deal with clash resolution and design challenges because these programs kept the lines of communication and accountability open. While technology can never replace the work designers do, it can significantly improve the ease and efficiency of our daily lives.

Lasting impacts

The use of technology on the Sound Transit Operations and Maintenance Facility changes what we see possible for the future of our industry. In watching our team show clients their project models and do live updates in 3D, we saw the design process streamlined. If more and more sites are modeled in BIM and clients have their own Geographic Information System (GIS) built into their plans already, this will help us see what we can fit into new designs and what we must work around.

The industry is moving toward relying on more detailed models because the live interaction and updates save time and money. This combination of technologies is exciting to clients and sub-consultants because it allows them to have a greater role in the design process and more insight into potential problems from day one. Through our work on the Sound Transit project, we’re proud to help drive this innovation by demonstrating what is possible when we use technology in expanded ways.