BIM for structural engineering: a complete guide to structural BIM

- What is structural BIM and how is it important in structural engineering?

- What are the benefits of using BIM in structural engineering?

- Challenges of adopting BIM in structural engineering

- How does structural BIM improve workflow and coordination?

- How to optimize structural designs using BIM

- Real-world uses of BIM in structural projects

- Which BIM software is best for structural engineers?

- What is the future of structural BIM in the industry?

- Frequently asked questions

What is structural BIM and how is it important in structural engineering?

The construction industry has undergone a strong paradigm shift from traditional design methods to intelligent digital workflows. Building information modeling has revolutionised structural engineering, transforming static drawings and disconnected calculations into multifaceted, data-rich 3D models. This transition has the potential to deliver measurable ROI through the reduction of errors, faster design cycles, and improved coordination, benefits that can easily scale from small residential projects to complex infrastructure developments.

Understanding BIM for structural engineering

Structural BIM creates intelligent, data-rich models where every element of the project includes embedded information about real-world properties and behavior. Unlike CAD drawings, which display only simple geometry, BIM models integrate structural specifications directly within the 3D representation, such as connection capacities, steel grades, concrete strength parameters, etc.

This centralized approach transforms engineering workflows with the help of automated coordination. When engineers modify the size of a beam, the system can automatically update all related calculations, material quantities, and connected elements. This removes the need for traditional manual updates throughout multiple documents and guarantees the consistency of the design throughout the project lifecycle.

Role of structural BIM in design and construction

Structural BIM serves as a coordination backbone between various building disciplines, aiming to prevent the expensive conflicts that can emerge when trades discover spatial interferences during construction that have previously gone unnoticed. The methodology also extends beyond the design phase and into construction planning, where contractors use BIM models to conduct sequencing activities, coordinate deliveries, and plan equipment operations.

The model can guide initial design calculations, and it can also be used later to inform construction crews about installation procedures and connection details. This versatility can be described as lifecycle continuity: support for facility management throughout building operations, with accurate structural capacity data for future maintenance tasks and renovation decisions without the need for expensive field investigation.

Modern implementations also have to align with international standards such as ISO 19650 and others in order to ensure the consistency of the data exchange process throughout global projects, as well as the establishment of clear information management protocols aimed at reducing various project risks.

Key components of BIM models in structural engineering

Comprehensive structural BIM models contain critical data layers that distinguish them from simple 3D geometry:

- Connection and load-bearing details specifying member joints, allowable stresses, and safety factors.

- Geometric and material properties defining shapes, sizes, strength characteristics, and performance specifications.

- Construction and compliance data covering installation sequences, temporary supports, and code requirements.

These integrated components create a unified information environment to replace separate databases, spreadsheets, and sets of drawings. Consolidation efforts like this can boost issue detection rates, improve consistency, and enable the sophisticated analysis of complete structural systems instead of isolated components, supporting everything from routine design verification to complex performance-based evaluations.

What are the benefits of using BIM in structural engineering?

An understanding of the capabilities of structural BIM leads directly to the examination of its tangible advantages in engineering practices. These benefits extend far beyond simple improvements to drafting, fundamentally transforming project delivery methods while offering competitive advantages for forward-thinking businesses. The technology has the potential to deliver measurable improvements in accuracy, efficiency, and risk mitigation that justify investments in implementation across diverse scales of project.

Enhancing collaboration among AEC professionals

Structural BIM transforms traditional sequential design processes into simultaneous collaborative workflows where architects, engineers, and contractors work within a shared digital environment. Team members have access to the same structural model from different locations, enabling real-time coordination that eliminates the delays inherent in linear project delivery.

Shared environments have the power to provide comprehensive project visibility throughout all levels of the team. Design decisions become transparent, contractors understand engineering rationale, and architects see how their vision translates into structural reality. This democratization of information access builds stronger working relationships while reducing conflicts from miscommunication.

Modern BIM platforms also have full support for risk mitigation measures, such as improved documentation and decision tracking. Clear audit trails of design changes and coordination decisions help protect companies from issues with liability while also offering evidence of due diligence in professional practice.

Improved structural analysis and performance

The integration of BIM elevates analysis capabilities through comprehensive data utilization and complex simulation environments. Engineers can perform dynamic analysis which considers the complex interactions between structural systems, environmental conditions, and operational loads with an incredible level of accuracy, something that simplified project models cannot achieve.

The technology enables performance-based design approaches in which engineers evaluate multiple alternatives against specific criteria rather than relying solely on prescriptive codes. This analytical capability leads to more resilient structures and optimized material usage while supporting innovative design solutions.

The integration of enhanced analysis also supports advanced modeling methods, including non-linear behavior, construction sequencing effects, and long-term performance predictions that can inform both immediate design decisions and lifecycle planning strategies.

Sustainable design practices with BIM technology

Environmental considerations have become extremely important differentiators in modern construction, and structural BIM provides powerful tools for the implementation of sustainable design. Its detailed material information can be used for precise lifecycle assessments and optimization strategies, minimizing environmental impact while maintaining overall structural performance.

BIM-driven sustainability extends beyond immediate project benefits to support the broader carbon reduction goals in the industry and the principles of the circular economy:

- Embodied carbon tracking enables informed decisions about structural systems and material selection.

- End-of-life planning facilitates future deconstruction and material recovery strategies.

- Precise material quantification eliminates over-ordering and reduces construction waste.

- Energy performance integration connects structural choices to operational efficiency outcomes.

- Supply chain optimization supports local sourcing and the reduction of the impact of transportation.

This comprehensive approach can position BIM-proficient firms as sustainability leaders while meeting increasingly stringent environmental regulations and client expectations for responsible design practices.

Challenges of adopting BIM in structural engineering

Despite the abundance of compelling advantages, the implementation of structural BIM also entails a number of transitional obstacles that engineering firms have to navigate in a strategic manner. These challenges can have a strong influence on the success of the implementation, necessitating careful planning. Understanding and preparing for these difficulties is what separates successful BIM transformations from abandoned initiatives, and proactive management can help in its own way to significantly reduce adoption risks.

High initial costs

The financial barriers extend well beyond BIM software licensing and include comprehensive infrastructure investment. Modern BIM workflows demand high-performance computing systems, advanced graphics capabilities, and robust network infrastructure, which can put a significant strain on budgets, especially those of smaller businesses.

Training represents the biggest hidden cost of implementation, often exceeding total hardware expenses. Effective implementation requires education programs covering software operation, workflow methodologies, and collaboration protocols. It is not uncommon for businesses to experience temporary productivity decreases during transition periods, as well, which is another element of the overall financial pressure from reduced billable efficiency.

Change management consulting and process restructuring add further costs that many companies tend to underestimate during initial budgeting, even though these investments tend to be absolutely critical for successful long-term adoption.

Need for skilled professionals

The structural engineering workforce faces a massive skill gap between the traditional methods of practice and the requirements of modern digital workflows. Experienced engineers possess deep technical knowledge but often lack BIM proficiency, while recent graduates have a great understanding of software tools but need plenty of mentoring in practical application and overall engineering judgment.

Successful BIM coordination requires professionals who combine structural expertise with technological skills, interdisciplinary communication, project management capabilities, and more. Hybrid skill sets like these are few and far between in the current market, creating challenges in both recruitment and retention.

Client resistance is another challenge, as engineers must often play the role of advocates for BIM adoption while managing client expectations about timelines, deliverables, and cost implications for the entire transition period.

Management and integration of complex data

BIM models contain vast interconnected datasets requiring sophisticated information governance protocols. Version control becomes more important than ever when multiple team members have the power to modify shared models, demanding disciplined procedures to prevent conflicts and ensure the complete integrity of business information.

The integration of legacy systems poses substantial challenges as businesses must maintain full compatibility with existing software ecosystems, as well as client requirements and project delivery methods. This dual-workflow requirement has a strong effect on the overall complexity of the implementation, rather than simplifying operations during transition periods.

Other noteworthy elements during the transition that can increase the difficulty of the adoption process include standardization efforts to establish consistent naming conventions and modeling procedures, information security measures to secure sensitive information without hindering collaboration, and quality assurance processes that must verify the accuracy and completeness of project models throughout different project phases.

Industry transition

The construction industry’s variable adoption pace creates its own coordination challenges between businesses that have different levels of BIM maturity. Structural engineers may invest heavily in capabilities only to discover that a lot of project partners still rely on traditional delivery methods, significantly limiting the positive effect of the new technology.

It is not uncommon for standardized contractual language to fail when it comes to addressing BIM-specific issues such as model ownership, liability for accuracy, or coordination responsibilities. Legal frameworks regularly lag behind technological capabilities, creating uncertainty about professional obligations and risk allocation that can deter adoption.

Timeline expectations frequently clash with implementation reality, as clients and project teams expect immediate productivity gains while businesses try to navigate learning curves and workflow adjustments that may extend over multiple project cycles before delivering the promised benefits.

How does structural BIM improve workflow and coordination?

Moving beyond implementation challenges, the successful adoption of BIM fundamentally transforms structural engineering workflows instead of simply digitizing pre-existing processes. The technology has the potential to reshape the way engineers approach project delivery, team coordination, and quality management. These workflow improvements deliver tangible productivity advantages and a reduction of project risks, which can be used to justify the investment costs across diverse types of practice.

Integrating BIM into your structural engineering workflow

The effective integration of BIM requires a systematic transformation of workflows that addresses process changes, team roles, and project delivery methods. Instead of forcing BIM into traditional workflows, successful firms try to restructure their approaches to leverage the technology’s collaborative and analytical capabilities.

The integration process typically follows a phased approach:

- Initial pilot projects establish basic modeling procedures.

- Coordination workflows are established or expanded.

- Project delivery is comprehensively transformed.

Change management becomes extremely important as the traditional boundaries between roles shift: junior engineers gain access to senior-level design information, while seasoned professionals have to adapt to new visualization and coordination methods.

Project delivery methods have a lot of influence over the success of workflow integration. Integrated project delivery and design-build contracts naturally align with BIM workflows from the start, but traditional design-bid-build approaches may require additional coordination protocols. Early contractor involvement should enable constructability input during design phases, maximizing the coordination benefits of BIM.

Quality control processes must evolve in order to address model accuracy, data integrity, and the verification of coordination. Establishing model review checkpoints at key project milestones ensures the translation of design intent while maintaining professional responsibility standards. These procedures become even more important when multiple team members work with and contribute to the same shared model.

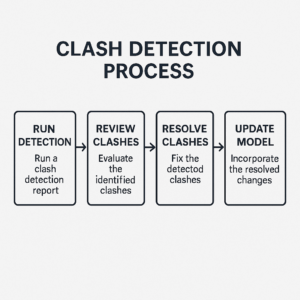

Enhancing coordination through clash detection

Proactive clash detection is BIM’s most transformative workflow capability, shifting conflict resolution from expensive field corrections to much more efficient design-phase issue resolution. Automated algorithms identify spatial conflicts, access issues, and installation problems before they can impact project budgets or construction schedules.

Regular coordination workflows integrate clash detection into standard project milestones. Weekly model updates and clash reviews replace traditional coordination meetings using focused problem-solving sessions with the assistance of visual 3D environments. Federated models combine architectural, structural, and MEP systems to provide comprehensive conflict identification capabilities across all building disciplines.

The technology can also extend beyond geometric conflicts to evaluate maintenance access, construction sequencing, and even future building modifications. Engineers can verify that there is adequate space for equipment installation, welding operations, or structural modifications throughout the building lifecycle.

The issue tracking systems integrated with BIM platforms not only document coordination decisions but also assign responsibility for resolution and verify that problems are solved. This systematic approach also creates easy-to-find audit trails in support of professional liability protection while ensuring comprehensive conflict resolution.

Evolution of project delivery and team coordination

BIM workflows redefine professional relationships and project delivery sequences for the entire construction process. Traditional linear phases, such as design, documentation, bidding, and construction, become overlapping collaborative sequences in which stakeholders have the opportunity to contribute toward shared objectives.

Real-time access to project models enables distributed team coordination in which architects, engineers, and contractors can work together regardless of their locations. In this way, project decisions can receive immediate input from different disciplines, which accelerates approval processes and improves design quality through the integration of diverse expertise. Other notable changes in this department include:

- The transformation of communication using visual model-based discussions

- The automated generation of construction drawings as a byproduct of design development

- Quality assurance improvements thanks to integrated checking procedures and model validation protocols

Construction administration benefits substantially from integration with BIM workflows. Field personnel can access model information from their mobile devices, verifying the accuracy of installation against design intent and communicating issues through visual documentation. As-built model maintenance processes can capture construction changes for future facility management applications with ease.

The transformation of workflows ultimately supports continuous improvement processes where the lessons learned from projects can inform future modeling standards, coordination procedures, and quality control measures for subsequent implementations. This iterative refinement helps firms maximize their productivity gains from BIM while maintaining the necessary levels of design quality and professional standards.

How to optimize structural designs using BIM

BIM’s comprehensive data environment is a treasure trove of unprecedented opportunities for systematic design optimization. Instead of accepting initial design solutions, engineers can now explore design alternatives in a methodical fashion, maintaining a balance between material efficiency, structural performance, and specific construction requirements. Strong emphasis on analytical methods transforms design decision-making from experience-based judgment calls to evidence-driven optimization processes.

Best practices for structural modeling with BIM

Effective structural optimization begins with disciplined modeling approaches that maintain a balance between requirements for detail and computational efficiency. Strategic modeling decisions significantly impact both the accuracy of the analysis and the potential for the optimization of the entire design process.

Parametric modeling techniques enable rapid design iteration by linking geometric properties to performance parameters. For example, if an engineer adjusts beam depths for deflection requirements, parametric relationships can automatically update not only connection details but also floor elevations and material quantities. This systematic connectivity helps maintain the consistency of the entire design while enabling highly-efficient optimization cycles.

Model organization strategies become critical for optimization workflows in their own right. Consistent element naming, logical grouping systems, and standardized parameter definitions can assist optimization algorithms with processing structural data more efficiently. Well-structured models are able to support both the manual exploration of the design without extensive reorganization and automated optimization routines.

Performance-based modeling approaches place a strong focus on capturing structural behavior which is essential for optimization objectives rather than concentrating on excessive geometric detail. This efficiency-oriented modeling helps complex optimization algorithms run within reasonable time frames while also maintaining a high level of design accuracy.

Making informed decisions with BIM data

BIM platforms provide comprehensive datasets that enable quantitative design evaluation that goes beyond existing experience-based methods. Engineers can systematically compare different design alternatives using many different objective performance criteria, as well as cost implications and material consumption metrics pulled directly from the model data.

Real-time quantity takeoff and cost estimation capabilities enable the integration of value engineering throughout design development processes. Engineers are able to evaluate the effect of design changes on not only material costs but also the complexity of construction and performance requirements in the long-term. This capability allows evidence-based design recommendations and client discussions with concrete data instead of general assertions.

Performance benchmarking capabilities also allow engineers to measure the success of optimization against specific criteria. Structural efficiency ratios, material utilization factors, and cost-for-performance metrics are all considered quantifiable measures of design quality, with support for continuous improvement efforts and professional development.

Integration with specialized analysis software can create optimization routines to consider realistic structural behavior, including dynamic response, non-linear effects, and complex loading combinations. When used appropriately, this method can produce practical solutions capable of maintaining structural integrity while achieving different optimization objectives.

Tools and algorithms for structural optimization in BIM

Modern BIM platforms integrate sophisticated computational methods that can automatically identify improved design configurations within the constraints defined by an engineer. Algorithmic optimization enables the systematic exploration of design spaces that human analysis could never practically examine without help.

BIM-integrated optimization tools can operate on multiple scales and objectives, from the sizing of individual components to the overall configuration of structural systems. Several of these optimization categories help engineers select appropriate methods for specific design challenges and project requirements:

- Topological optimization determines the optimal material distribution patterns for complex loading conditions and geometric constraints.

- Size optimization identifies efficient dimensions of components while satisfying strength, serviceability, and code requirements.

- Shape optimization refines structural geometry in order to boost performance characteristics or reduce total material consumption.

- Multi-objective optimization attempts to find a balance between competing goals such as weight reduction, cost optimization, and environmental impact.

- Configuration optimization explores alternative structural systems, connection types, and load path arrangements.

Cloud-based optimization services extend the computational capabilities beyond the limitations of singular workstations, making it possible for complex optimization issues to be resolved within typical project schedules. These services can process multiple optimization scenarios at the same time, providing engineers with comprehensive comparisons of alternative designs.

Generative design algorithms represent the most advanced optimization approach by far, with the power to explore thousands of design configurations without disrupting the existing engineering constraints. These systems have the potential to discover innovative structural solutions that conventional design approaches may never consider in the first place, which is a particularly valuable feature for potentially complex geometries or unusual loading conditions.

Performance validation workflows integrate the results of optimization efforts with the verification of structural analysis, ensuring that the optimized designs meet all safety and serviceability requirements. A systematic approach to performance validation offers confidence in the outcome of optimization while maintaining current professional responsibility standards.

Real-world uses of BIM in structural projects

Practical applications of structural BIM demonstrate the technology’s transformative impact across many project challenges. They showcase exactly how BIM can address specific structural engineering problems that existing methods struggle to solve in an effective way. Understanding these applications may help engineers identify various opportunities for the adoption of BIM within their practice areas while showcasing measurable project improvements at the same time.

Complex geometric structures represent one of the most interesting advantages of BIM, where irregular forms and intricate spatial relationships demand a high level of precision in coordination. Projects like the Guggenheim Museum Bilbao demonstrate how BIM enables structural systems that support architectural vision while maintaining constructability, achievements that would have been nearly impossible with traditional methods. The flowing titanium surfaces necessitated highly precise structural coordination, which was facilitated by BIM using integrated design and analysis workflows.

Historic preservation and renovation projects benefit greatly from BIM’s ability to manage hidden conditions and incomplete documentation. Laser scanning combined with BIM modeling can create accurate digital representations of existing structures, enabling engineers to design changes with respect for historical significance while meeting all the necessary performance requirements. The renovation of the London Victoria Station in Brighton is a good example of how BIM can facilitate complex structural upgrades within preservation constraints.

Seismic retrofitting applications highlight BIM’s analytical integration capabilities for performance-based design. Engineers can use detailed BIM models to assess existing building capacity, identify vulnerable elements, and design targeted strengthening measures where applicable. California’s seismic retrofit programs demonstrate the systematic evaluation of buildings and optimization strategies that maximize structural improvements while controlling costs.

Prefabricated and modular construction is a rapidly expanding field of BIM applications where digital models can drive manufacturing processes. Steel fabricators and precast manufacturers are able to extract precise specifications directly from structural models for the purpose of programming automated equipment, eliminating traditional shop drawing phases. This digital-to-manufacturing workflow achieves dimensional precision, reduces fabrication errors, and optimizes delivery schedules at the same time.

Infrastructure and bridge projects leverage BIM for managing multiple structural systems – foundations, substructures, and superstructures – while accommodating utilities, drainage, and construction sequencing. Cable-stayed and suspension bridge projects benefit the most from the ability of BIM to coordinate complex geometry and construction processes that existing methods could not process at the same level of efficiency.

Emerging applications in mass timber construction, 3D-printed structures, and adaptive reuse projects demonstrate BIM’s expanding capabilities. These applications showcase the technology’s flexibility in addressing newer construction methods and materials while maintaining structural performance requirements.

Measurable outcomes from these applications include substantial reductions in design coordination time and the number of construction conflicts together with massive improvements in the accuracy of fabrication processes. These quantifiable benefits demonstrate BIM’s practical value across diverse structural engineering challenges.

Additional specialized applications continue to expand BIM’s influence throughout structural engineering practice. These applications demonstrate the technology’s flexibility when it comes to addressing specific project challenges and performance requirements:

- High-rise construction necessitating complex core designs, outrigger systems, and the integration of curtain walls with structural framing.

- Sports and entertainment facilities demand long-span structures, dynamic loading analysis, and specialized equipment coordination.

- Industrial and process facilities entail heavy equipment loads, vibration control requirements, and the integration of complex piping.

- Healthcare construction requires precision structural systems, infection control considerations, and advanced MEP coordination.

- Data centers need specialized structural systems, the coordination of equipment support, and future expansion capabilities.

- Temporary structures are sometimes required to assist construction processes, event facilities, and emergency response applications.

These specialized applications often combine several BIM capabilities at once to address unique project requirements, demonstrating the technology’s comprehensive problem-solving potential.

Which BIM software is best for structural engineers?

The landscape of structural engineering software has a large number of different BIM platforms to choose from, and each has distinct capabilities, workflows, and approaches to integration. Selecting the appropriate software significantly impacts the success of implementation, productivity gains, and long-term project outcomes. Engineers have to evaluate their options based on their specific project types, team sizes, collaboration requirements, and also the existing technological infrastructure.

Top BIM software tools for structural modeling

Autodesk Revit for Structural Engineering dominates the North American market with its comprehensive integration with the architectural and MEP disciplines. The software excels in building projects where multidisciplinary coordination takes precedence over advanced structural analysis. The parametric modeling environment of Revit enables rapid design iteration while maintaining relationships between structural elements and building systems. Its massive library of structural components and standardized connection details plays its own part in accelerating modeling processes for a lot of typical building projects.

The platform’s analytical capabilities focus primarily on gravity load analysis and basic lateral force distribution. Engineers requiring complex structural analysis typically supplement Revit with specialized software, such as ETABS, SAP2000, or STAAD.Pro. This workflow involves exporting structural geometry from Revit, performing detailed analysis in specialized software, then importing the results back for member sizing and documentation.

Tekla Structures takes the opposite approach, prioritizing structural detailing and fabrication over architectural integration. The software creates highly detailed structural models containing precise connection information, fabrication details, and material specifications. Tekla’s biggest strength is in its handling of complex steel and precast concrete projects, where fabrication accuracy and construction coordination are paramount.

Tekla’s modeling environment requires more technical expertise than that of Revit, but it offers superior control over structural details in compensation. The software has the ability to generate comprehensive fabrication drawings, material lists, and CNC machine instructions directly from the structural model. This makes Tekla particularly valuable for design-build projects and businesses with fabrication partnerships.

Bentley MicroStation also takes a unique approach to BIM features, offering powerful capabilities for infrastructure and complex building projects. It can work in large-scale projects with ease, offering robust integration with civil engineering workflows. Bentley’s integration of analysis through STAAD and RAM products creates a comprehensive structural design environment particularly suited for infrastructure applications and international projects.

Comparing BIM software options for structural design

The selection of software in the B2B sphere is a challenging process that necessitates a delicate balance between multiple factors that can vary significantly. Integration capabilities often determine software choice more than individual features, as structural engineers rarely work in isolation.

Project scale influences the appropriateness of software considerably. Small to medium-sized building projects tend to benefit from Revit’s streamlined workflows and architectural integration, while more substantial infrastructure projects may require Bentley’s robust handling of complex geometry and extensive coordination requirements. Tekla also has its own niche in this case, excelling in projects where fabrication precision outweighs design speed considerations.

Collaboration requirements also play their part in software decisions. Projects involving multiple design firms tend to gravitate toward widely adopted platforms such as Revit to ensure a high degree of compatibility. International projects, on the other hand, may require software that supports various regional standards and workflows on top of regular interoperability concerns. The influence of cloud-based collaboration capabilities on software selection is also growing as teams become more and more distributed and the industry evolves toward a more digital approach.

Learning curve considerations affect the success of implementation in their own way. Revit’s interface has many similarities with well-known architectural software, which can simplify adoption to a certain degree for engineers transitioning from 2D CAD environments. Tekla demands more specialized training but provides superior control over modeling processes for experienced users, and Bentley tends to require the most training of them all, but it also has the widest range of engineering capabilities.

Cost structures vary substantially between platforms, affecting both the initial adoption and long-term budgeting efforts. Subscription-based licensing provides predictable costs but may result in an increase in the total cost of ownership. Perpetual licensing options provide better control over software costs but are often limited when it comes to software updates and new features (along with the fact that more and more solutions are phasing out their perpetual licensing options as time goes on). Cloud-based services are a viable option, as well, with a strong focus on usage-based pricing, which may be the best option for businesses with highly variable workloads.

Coordination and collaboration platforms such as Revizto serve an essential role in this BIM ecosystem, facilitating multidisciplinary collaboration and project communication when specialized solutions lack these capabilities out of the box. While it is not primarily modeling software, Revizto has the power to enable real-time collaboration on federated BIM models, allowing structural engineers to coordinate with architects and contractors via a shared virtual environment. These platforms help bridge the gap between different BIM creation tool sets while offering centralized spaces for issue tracking, design reviews, and construction coordination. The growing importance of tools like Revizto reflects the industry’s recognition that success with BIM depends on both individual modeling capabilities and workflow coordination, improving the lifecycle value of BIM data.

Integration with existing software infrastructure can determine practical software choices regardless of pre-existing preferences. Businesses invested in Autodesk ecosystems will find Revit integration the most compelling, while those used to Bentley’s civil engineering software would naturally gravitate toward MicroStation’s software solutions. Even Tekla has its own niche from this point of view, appealing to companies focusing on steel construction due to the software’s strong fabrication partnerships.

What is the future of structural BIM in the industry?

The current trajectory of development of structural BIM points toward a fundamental transformation of the industry via artificial intelligence, the automation of design processes, and real-time performance monitoring. These technological convergences promise capabilities that extend far beyond current implementations of BIM. Understanding emerging trends will enable engineers to prepare for the changes that will reshape professional requirements and competitive advantages within the next 5-10 years.

Emerging trends in BIM technology for structural engineering

The integration of Artificial Intelligence represents the most significant near-term development, with machine learning algorithms beginning to automate routine design tasks and identify optimization opportunities that human analysis might miss. AI-powered systems are on their way to begin reviewing structural models for code compliance, suggesting design improvements based on performance databases, and generating preliminary structural layouts from architectural constraints in the near future.

Advanced automation extends beyond design into construction and operations. Robotic construction systems are going to start interpreting BIM models directly for automated fabrication and assembly, while autonomous quality control systems will verify construction accuracy against digital specifications. These developments require BIM models with an unprecedented level of detail and accuracy, driving new data-rich modeling standards and verification protocols.

The maturity of the digital twin process is transforming static BIM models into dynamic representations of buildings that evolve throughout structural lifecycles. Sensor networks will feed real-time performance data into BIM environments, enabling predictive maintenance strategies and structural health monitoring that anticipates issues before they can impact building operation workflows. This integration will also require new data management capabilities and professional expertise in the integration of building systems.

Advances in interoperability through the evolution of standards like ISO 19650 and emerging protocols will eliminate the limitations of software compatibility that the industry has today. Universal data exchange will enable seamless collaboration regardless of platform choice, while blockchain integration may offer secure, verified design decision tracking with support for professional liability management and regulatory compliance.

Regulatory and economic transformation

Building codes and standards will increasingly require BIM-based submissions and performance verification, particularly for complex structures and sustainable design compliance. Regulatory agencies are developing BIM review capabilities that will streamline permitting processes while demanding higher model accuracy and completeness standards.

Economic drivers including carbon regulations, material cost optimization, and construction labor shortages will accelerate the adoption of BIM among businesses that are still resisting implementation. Performance-based contracts tied to BIM-verified outcomes will become standard, requiring comprehensive digital documentation and analysis capabilities that traditional methods cannot offer.

Insurance and liability frameworks will evolve to recognize BIM-based design verification and risk assessment, potentially providing reductions in premiums for companies demonstrating comprehensive digital design processes and quality control measures.

Preparing for the future: strategic actions for engineering firms

Planning for technological infrastructure must anticipate computational requirements for AI-generated design tools, real-time collaboration platforms, and advanced analysis capabilities. Companies should evaluate cloud computing strategies and data management protocols that support future scalability without requiring complete system overhauls.

Professional development priorities should focus on interdisciplinary collaboration skills, as well as data analysis capabilities and familiarity with emerging technologies. Engineers do not have to become full-fledged programmers, but understanding API integration, database management, and IoT systems will become valuable for maximizing BIM capabilities and career advancement.

The adaptation of business models requires the evaluation of how AI automation and improved efficiency are going to affect project delivery methods, fee structures, and competitive positioning. Forward-thinking companies should consider how enhanced capabilities enable premium services, the expansion of project types, or improved profit margins that justify technology investments.

Successful preparation involves the strategic adoption of technology that balances early adopter advantages against implementation risks. The following preparation strategies position firms for future competitiveness while maintaining current operational effectiveness:

- Staff development programs for scalable computing, data storage, and collaboration capabilities.

- Client education initiatives demonstrating value propositions and competitive advantages.

- Incremental capability building via pilot projects and selective technology adoption.

- Evolution of quality systems incorporating new verification methods and professional responsibility protocols.

- Development of partnership with technology vendors, fabricators, and forward-thinking clients.

All these strategies will enable businesses to navigate the transformation of the industry proactively rather than reactively, positioning them as leaders in an increasingly competitive and technology-driven marketplace.

Frequently asked questions

How does BIM support seismic and wind load analysis in structural engineering?

BIM platforms integrate with specialized analysis software to enable comprehensive seismic and wind load evaluation using detailed structural models. The detailed material and geometric information within BIM models supports sophisticated analysis methods capable of considering building irregularities and performance-based design criteria.

Can BIM be integrated with structural health monitoring systems?

Modern BIM platforms connect with sensor networks to create digital twins that feed real-time structural performance data back into the model. Engineers can monitor stress levels and track structural movement through dashboards which combine BIM visualization and live sensor data for predictive maintenance.

What role does BIM play in prefabrication and modular construction for structural projects?

BIM offers precise dimensional control and manufacturing integration by driving automated fabrication equipment directly from structural models. The technology enables mass customization where each prefabricated element can be uniquely configured while maintaining manufacturing efficiency and quality control.

Unlock seamless BIM collaboration — request your demo today