Building healthcare from the ground up—and the shop floor out

Pitt Meadows Plumbing is a leading mechanical contractor specializing in plumbing, HVAC, and industrialized construction. The Canadian company pioneers offsite fabrication techniques using advanced BIM/VDC technology and state-of-the-art fabrication facilities.

Transforming hospital construction with Revizto-powered prefabrication and coordination

Hospital construction stands as one of the most complex challenges in the built environment, where MEP systems must integrate flawlessly within exacting tolerances. For Pitt Meadows Plumbing (PMP), the Cariboo Memorial Hospital Redevelopment Project in Williams Lake, British Columbia, Canada, showcases the mastery of their manufacturing-based construction approach. By leveraging Revizto as the central collaboration platform from design through fabrication and installation, PMP coordinated multi-trade prefabricated racks and enabled seamless communication across their entire organization and project team.

In search of seamless coordination

The Cariboo Memorial Hospital Redevelopment Project is a four-story expansion to the existing hospital in Williams Lake, BC, serving not only the city but also the Cariboo Chilcotin and 100 Mile House Local Health Areas, within the traditional territories of the Secwepemc (Shuswap Interior Salish) First Nation. Carefully phased to maintain uninterrupted hospital services, the project incorporates new emergency department facilities, medical/surgical inpatient units, maternal and women’s health services, mental health and substance use beds, pharmacy services, and academic space for the University of British Columbia.

But this expansion is about more than just steel and concrete—it’s about digital innovation. As Pitt Meadows Plumbing leads the complex build, they’re harnessing cutting-edge technology to redefine hospital construction. At the heart of their approach is Revizto, enabling seamless coordination across teams, turning challenging hospital corridors into modular masterpieces and ensuring every pipe, duct, and detail fits perfectly before ever reaching the site. The result? A project that’s setting a new benchmark for construction efficiency and teamwork.

Revizto has been a cornerstone of the whole Cariboo Memorial project. We’ve used it for every piece of coordination on this project.

Synchronizing teams, models, and fabrication

Hospital projects demand precise MEP coordination in notoriously tight spaces. For Cariboo Memorial, Pitt Meadows Plumbing elevated this challenge by enabling a cross-trade industrialized construction approach centered on level of development (LOD) 400+ models—highly detailed 3D representations capturing every component down to individual fasteners and connections.

These detailed models became the foundation for deck layouts using total robotic stations, multi-trade fabrication, and offsite fabrication of piping and HVAC systems. The centerpiece of this approach: multi-trade racks built entirely in Pitt Meadows Plumbing’s fabrication shop. Each eight-foot-wide prefabricated module—built to hospital corridor width requirements—arrives onsite with all MEP components fully integrated.

For Pitt Meadows Plumbing, offsite fabrication has long delivered faster schedules, lower costs, and cleaner execution than traditional stick-built methods. But their evolution toward fully industrialized construction required solving a critical puzzle: connecting BIM coordinators, shop fabricators, trade partners, and field teams around a single source of truth.

Early in their journey, Pitt Meadows Plumbing attempted to fabricate directly from Revit models—a challenging approach that required superintendents and foremen to navigate complex modeling software. The company needed a platform that could bridge the gap between detailed engineering models and practical shop floor and field use.

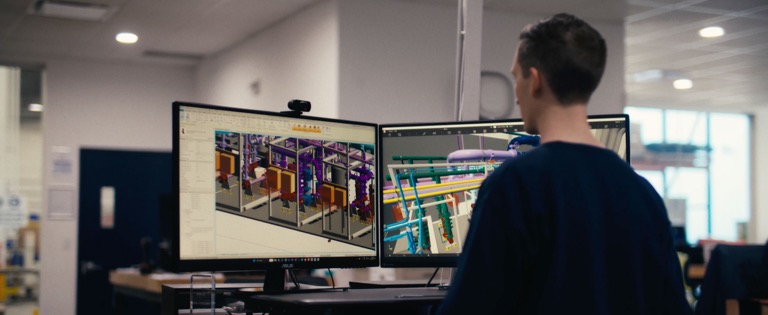

Revizto became that solution, transforming workflows seamlessly from pre-design through construction. The platform's ability to automatically sync models across all devices meant that fabricators in the shop, superintendents in the field, and BIM coordinators in the office all worked from the same up-to-date information.

"With Revizto, we can actually see an update today of what the modeling person has done this morning," says Steve Robinson, President and Founder of Pitt Meadows Plumbing.

Revel adds, "The BIM team can upload a model at the end of each day, and we know that's going to hit everybody's device across the whole organization."

This daily synchronization meant that fabricators in the shop, superintendents in the field, and BIM coordinators in the office all worked from the same up-to-date model.

It's fantastic having the Revizto 3D model for our site team, for our shop team, for our BIM team, to use as a collaboration tool.

Multi-trade coordination as project host

As the mechanical contractor, Pitt Meadows Plumbing coordinates the largest and most complex building systems—ductwork, drainage with slopes, and piping that have minimal flexibility for change. On the Cariboo Memorial Hospital project, the trade contractor took on the role of model host, bringing together the general contractor, electrical contractor, and other trades for comprehensive coordination.

Robinson describes the power of real-time connections: "Revizto allows us to have members of the complete construction team work together as the model is constructed. We can see what our decisions do to each member of the team as we make a change—people can immediately see the clash and the change to be made immediately."

The team conducted weekly coordination meetings using Revizto's full suite of collaboration tools—stamping tool, markup tool, assignees, ports, and tags. This proactive coordination approach ensured potential conflicts were identified and resolved before reaching the field.

As a site superintendent, the thing I like most about Revizto is the collaboration with the other trades and the coordination that we're able to get on the spot. We’re all able to get together to organize it, coordinate it, and get back out and do our jobs properly.

3D visualization and detail-level modeling

Traditional construction relies on 2D drawings that require workers to mentally translate flat plans into three-dimensional reality. At the Cariboo Memorial Hospital, Pitt Meadows Plumbing focused on 3D-first workflows, with field teams building directly from the model rather than from paper drawings.

The project utilized LOD 400+ models, capturing every component down to the smallest detail. This level of precision was essential for the multi-trade rack prefabrication and for coordinating the complex hospital systems.

Matt Main, Senior BIM Manager at Pitt Meadows Plumbing, emphasizes how the detailed Revit models of the multi-trade racks are exported seamlessly to Revizto. Where 2D drawings might show a generic pipe symbol, the LOD 400+ model contained the exact pipe size, material, fittings, hangers, and connections—all spatially accurate and ready for fabrication.

One of the most transformative aspects of the platform's implementation was its ease of use on iPads in the field. “Revizto has been a major part of this project. I would say most of our employees mainly use Revizto and not so much 2D drawings. It’s super easy to use on the iPad,” says Kirkland. The 2D overlay feature proved particularly valuable, allowing teams to view traditional drawings overlaid on the 3D model and see all sheet details in context.

This accessibility extended beyond Pitt Meadows Plumbing’s own teams. Justin Nguyen, Project Manager with Evergreen Sheet Metal, notes, "The Cariboo Memorial Hospital is definitely the most impressive project I've worked on so far in terms of complexity. I was amazed that we were able to see every component on the model down to the smallest detail.”

When Pitt Meadows Plumbing introduced us to Revizto, we were unfamiliar with it, to be honest. But when management took us over and let us watch it live, it was an ‘aha’ moment, and we thought, this is where we have to go.

Shop-to-field integration

The integration between Pitt Meadows Plumbing's fabrication shop and field operations represents the pinnacle of their industrialized construction approach. Using Revizto, the team maintained continuity from design through fabrication to installation.

This direct connection between the model and fabrication machinery eliminates interpretation errors and ensures that what's built in the shop matches precisely what's in the coordinated model.

Every piece of duct, every piece of pipe, flows out of the model to machinery. We know that they are installed exactly the way the model says, because we don't have somebody else interpreting what that final product should look like between the model and the fabrication tool.

Issue Tracking and accountability

Revizto’s powerful collaboration tools have transformed the project team’s approach to managing issues and coordination. Team members no longer work in silos; instead, they can tag issues to each other, assign tasks back to the responsible trades, and track resolution seamlessly across the platform.

The immediate communication within Revizto ensures that everyone can instantly see the consequences of design changes. Additionally, the 2D/3D overlay feature further enhances accountability, enabling teams to reference specific drawings and model locations when flagging or resolving issues. Together, these capabilities drive more transparent communication, quicker conflict resolution, and true accountability throughout the entire construction process.

Issue tracking has had a massive impact on just how we collaborate across the project.

Democratizing the model

A critical success factor was making everyone—regardless of role or trade—feel like a genuine stakeholder in the model’s development. With Revizto, Pitt Meadows Plumbing broke down traditional barriers between field and office, encouraging wide participation and shared ownership.

Robinson describes this cultural shift: “What we find very important is that people who are actually doing the work feel that they're part of the process to develop what that model looks like. That's the biggest reason we like it. It offers everybody on the project an opportunity to comment.”

By providing every team member—from BIM experts to field tradesmen—with instant access to the latest models and the ability to annotate, comment, and flag issues, Revizto ensures that insights and feedback come from those closest to the work.

This approach increases buy-in, improves model accuracy, and fosters a spirit of collaboration that keeps everyone invested in project success. The platform’s transparency also helps trades coordinate and adapt with ease, building trust and ensuring everyone’s voice is valued throughout the project lifecycle.

In my opinion, Revizto is the best piece of software out there for model review and collaboration.

Partners in Innovation

The Cariboo Memorial Hospital project reinforced a critical lesson for Pitt Meadows Plumbing: successful industrialized construction depends on choosing partners who can keep pace with innovation. The right tools don't just solve today's challenges—they scale across an entire organization.

As James Zelinski, VP of Administration at Pitt Meadows Plumbing, notes: "Our mission is to build industry-leading teams. We need partners that can help us collaborate across our entire network of projects, and we believe that Revizto and their innovative technology helps us make our people better every day."

One of the important factors for us to choose partners who we work with are people who are leading the industry. We consider ourselves innovators in our field, and we lead. And so we've chosen specifically to work with people like Revizto.