What We Do

Connecting all project members on one platform

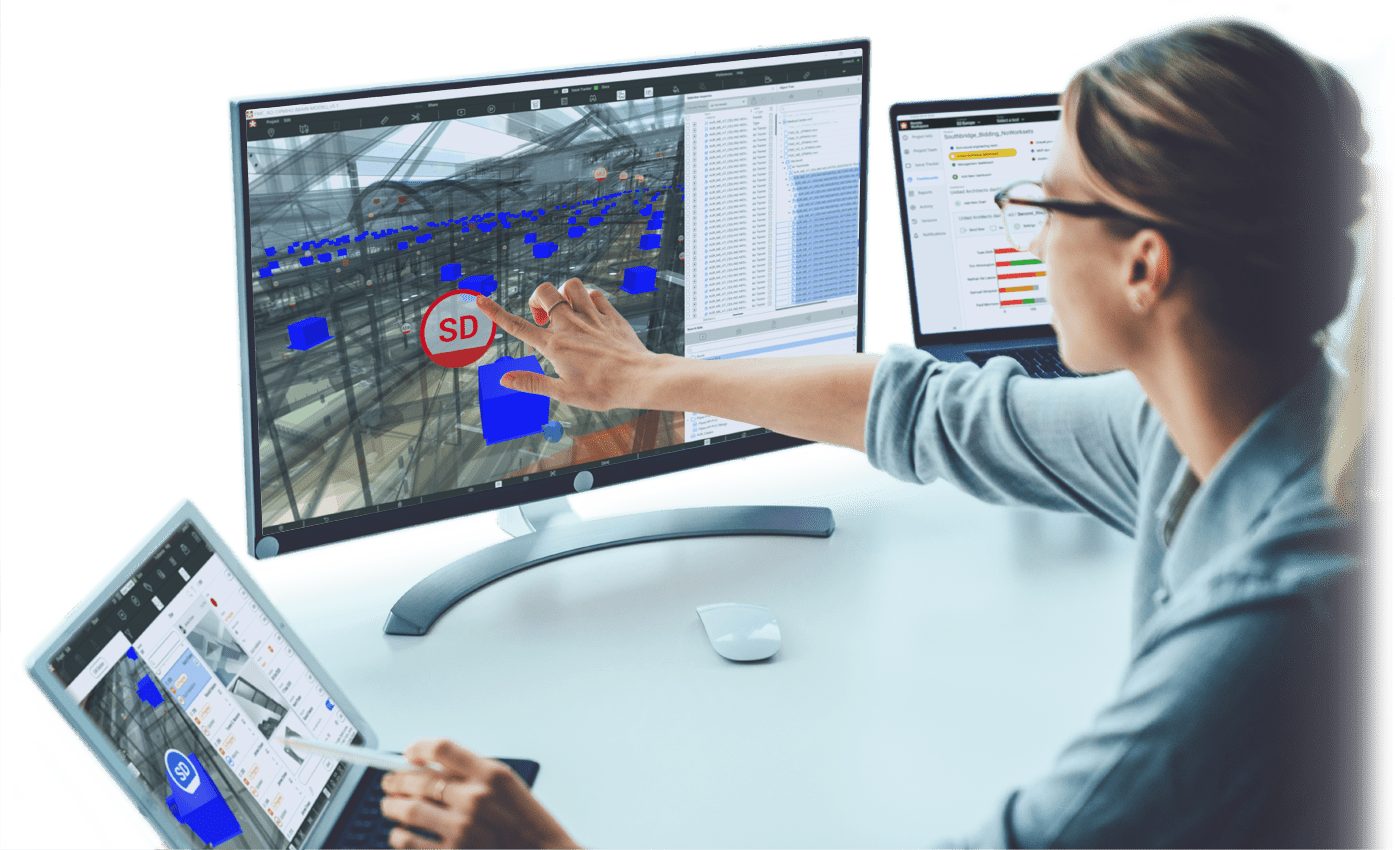

Revizto unifies BIM intelligence and makes it immediately accessible and actionable for the entire project team. With Revizto’s advanced Issue Tracker project team members can identify and manage model-based issues in the 3D space and 2D sheets, including addressing clash groups. Revizto provides unified access to a project’s data both for 2D and 3D workflows, so anyone can use it depending on project requirements.

Who We Are

Single Source of Truth for Any Project

Central Hub for All Models

View the entire project by federating all intelligent BIM data including reality capture into a centralized user-friendly location and get all teams in-sync.

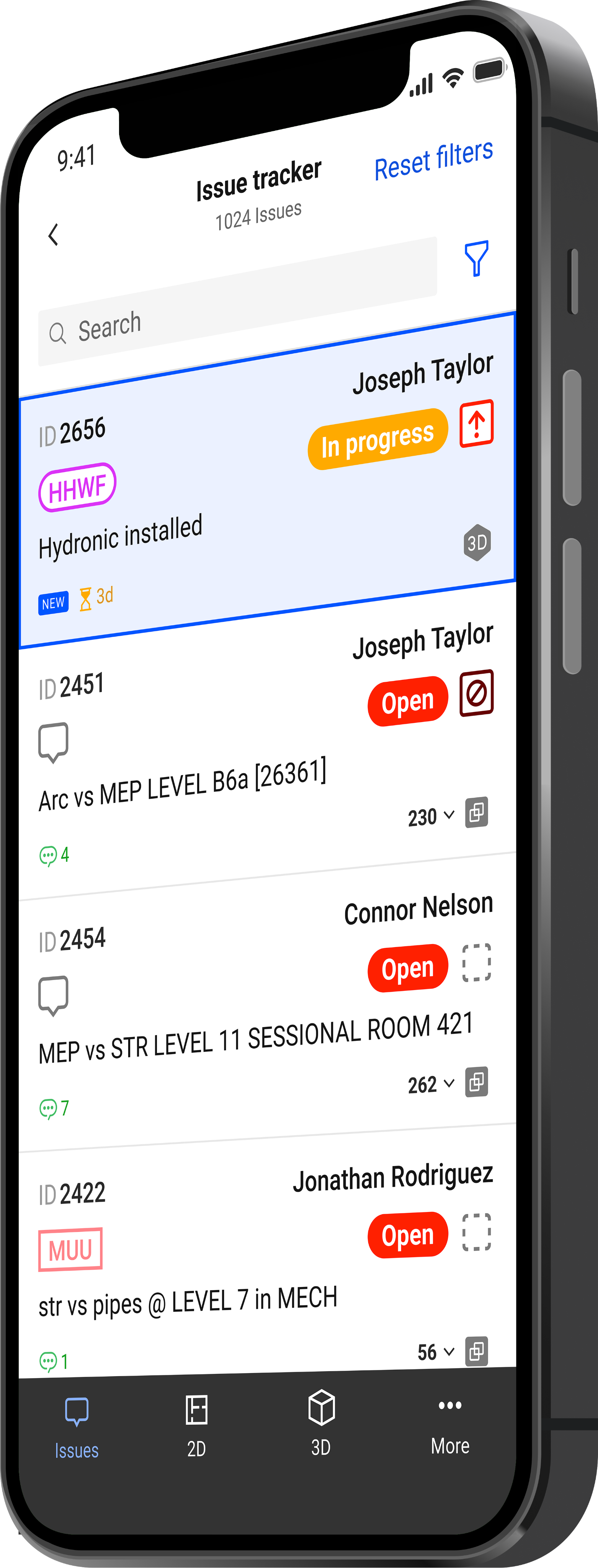

Real-time Issue Tracker

Easily standardize the way data moves through the project and effectively communicate model-based tasks with the team.

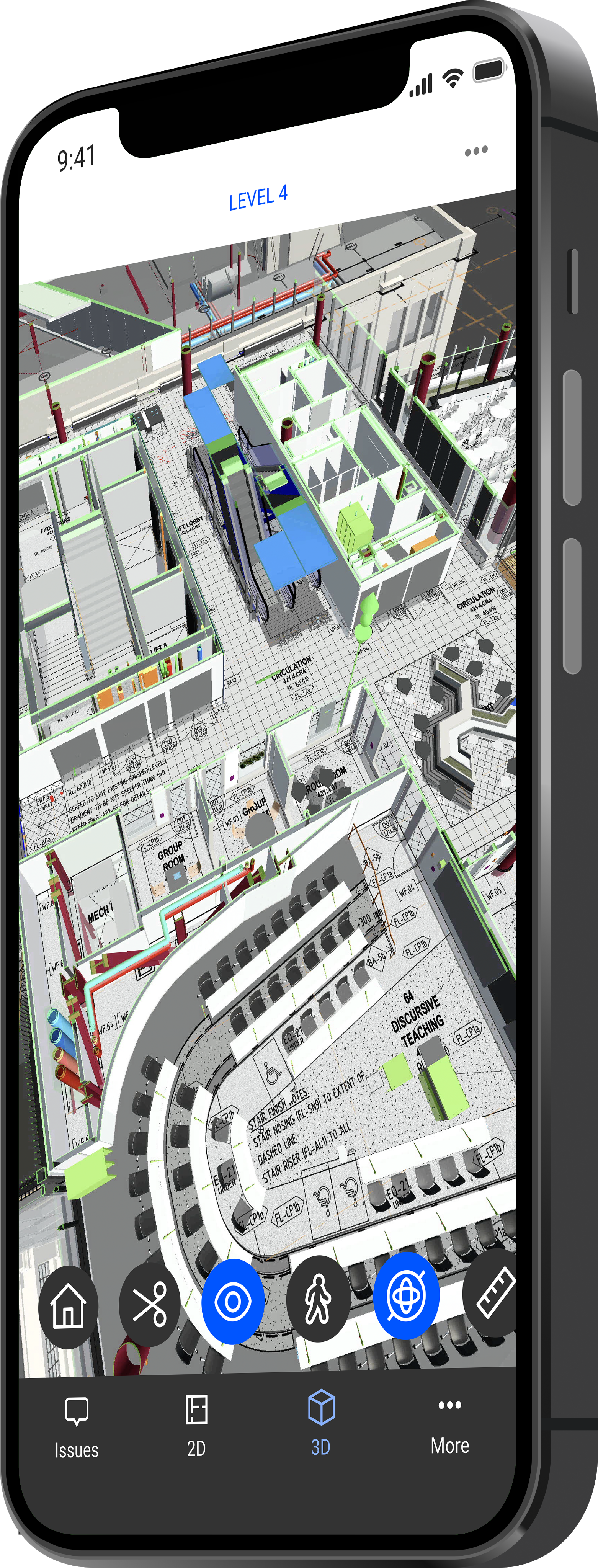

2D/3D Model Synergy

Leverage a unique 2D/3D combined view, easily compare 2D sheets and work with live CDE documentation seamlessly from inside Revizto.

VR Immersive Experience

Explore real-model data and coordination issues by leveraging Revizto’s immersive, true-to-scale VR experience within seconds!

Clash free projects

Use an integrated solution that combines clash detection, grouping, workflow builder and issue tracking into a single environment.

Collaboration from Anywhere

Contribute from the office or on-site. Keep all trades on task and monitor their progress in the field and access all the project data on a mobile device.

Our Compatibilities

Plugins

Supported Formats

CDE Integrations

Industry Partners

Industries We Serve

Airport

Effortless communication for complex airport builds and reconstruction projects.

Learn More

Infrastructure

A better way to collaborate on large infrastructure projects, from day one through the project lifecycle.

Learn More

Commercial Buildings

Offer a new way for your teams to execute large commercial projects around the world.

Learn More

Residential

Seamless coordination to help build safer, and more efficient buildings for our communities to live in.

Learn More

Historical Restoration

A single platform that helps restore the past and ensure a long-term future for societies' special projects.

Learn More

Healthcare

Project coordination that allows teams to build better environments for medical professionals.

Learn More

Sport & Entertainment

Find and resolve issues earlier on in your large sport and entertainment projects.

Learn More

Transportation

Help data, models, and information travel anywhere project team members are - with no roadblocks.

Learn More